As the world moves towards making more eco-friendly responsible choices, the demand for sustainable and renewable energy has driven consistently high growth in the solar inverter market.

A solar inverter (also called a photovoltaic or PV inverter) converts direct current (DC) into alternating current (AC) and is widely used in solar photovoltaic power generation systems.

Solar inverters available today are generally divided into three types: central inverters, string inverters and micro-inverters.

We would like to introduce UF Capacitors’s passive components and show how they can contribute to optimizing the design of string inverters.

Standard Film Capacitors

Regardless of the type of solar inverter, the key requirements are high efficiency, high reliability and input voltage with a wide range of capacitance values.

This contribution of attributes is exactly why UF Capacitors’s various metallized PP film capacitors can play an essential role in a solar inverter’s circuit design as they feature a large current handling ability, high reliability and proven safety performance. Our capacitors are used for input & output filtering, EMI suppression, snubber and DC link circuits

On the input side of the primary DC filter circuit ① as well as for the DC-link circuit ⑤, DC-rated TDA series film capacitors provide DC filtering. Parts with voltage ratings of up to 1300VDC and a wide capacitance range of up to 110μF are available as one single component; both 2-pin and 4-pin terminal solutions are available.

On the input side of the DC/DC converter circuit, as well as in snubber circuits (② + ④in Figure 1), DC-rated TDA series (coating type), X2 THB (box type) film capacitors, are ideal solutions for smoothing. Various rated voltage values are available from 450VDC up to 1100VDC.

The capacitance range stretches from 0.01μF up to 12μF. Excellent safety performance (thanks to a built-in fuse function – see Figure 2.), high-frequency characteristics and high ripple current capacity help these three film capacitor series devices to optimize the high voltage circuit of a solar inverter. AC-rated TDA series film capacitors with a higher rated voltage range of 250VAC to 600VAC are also available. This industrial-grade AC capacitor can be used as an output filter.

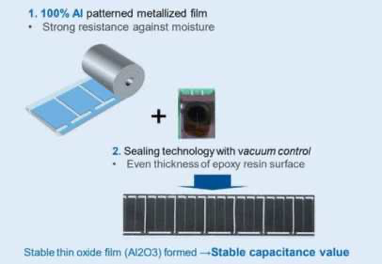

Considering that reliability – especially in humid conditions – is critical for solar inverters which are used outdoors, UF Capacitors has developed its own enclosure sealing technology and 100% aluminium vapour deposition processes which enable our film capacitors to achieve high humidity resistance – see Figure 3

We are committed to high output, high safety and high reliability, so UF Capacitors’s film capacitors can help optimize your solar inverter design.

TMA/TMB (Polymer Aluminum Capacitors)

UF Capacitors TMA/TMB conductive polymer solid aluminium capacitors play a major role in the optimization of solar inverters. To efficiently generate energy from the sun, the solar panel must absorb energy from the sun continuously as the earth rotates. By detecting and tracking the live position of the sun and adjusting the angles of the panel to ensure that it always faces the sun the solar energy harvest can be maximized.

Conventional solar inverters have a centralized power conditioner that controls the entire module.

New requirements that these micro-inverters demand include a long lifetime of 5-10 years, space-saving, and cost-reduction. TMA/TMB capacitors satisfy these new requirements.

A single TMA/TMB capacitors can replace seven MLCCs in a micro-inverter design, reducing PCB space by 31% . Another benefit of using TMA/TMB is that capacitance is not reduced, unlike MLCCs which cause a reduction of capacitance due to DC-Bias.