Smart power meter as a smart grid information system structure system, the most basic collection equipment. It is generally composed of measurement unit, data processing unit, communication unit, power supply unit and so on. The clock module is driven by the energy provided by the power grid, and when the power grid is in maintenance or blackout, the built-in clock power supply of the power meter needs to guarantee the normal operation of the clock module.

As a recyclable energy storage device different from batteries, supercapacitors are widely used in electronic meter power meters as a backup energy source to guarantee the accuracy of the clock module. Supercapacitor can not only meet the harsh working temperature requirement of -40℃~+85℃ for smart energy meters. Its long working life also provides a reliable guarantee for the long-term reliable operation of the smart energy meter, more importantly, the supercapacitor itself for the considerable specific energy and relatively simple charging and discharging management circuit design, greatly simplifies the rtc backup power supply design, in the original lithium battery based on supercapacitor is very ideal backup power supply supplement. On-the-spot supercapacitors are also widely used in other types of MCUs to keep the RTC. At present, the intelligent single-phase meter of the State Grid has explicitly proposed the use of supercapacitors as a backup power source for RTC maintenance. Keep the RTC running accurately for more than 48 hours to achieve the purpose of built-in battery replaceable

Supercapacitor is composed of two isolated insulated porous electrodes, and an electrolyte containing a large number of ions. The principle is different from ordinary electrolytic capacitors, only electrostatic ion migration exists in the energy storage process, and no redox reaction occurs.

Structure

Supercapacitors are generally composed of electrodes, electrolyte, diaphragm and other auxiliary materials.

Electrode as the most important part of the supercapacitor, generally consists of fluid collector, active material, conductive adhesive composition. Collector as a structure to support the active material for the output of electrons, not with the electrolyte chemical reaction, generally use conductive metal, most commonly used in the manufacture of aluminum.

The active material is generally activated carbon, used for adsorption of ions, energy storage, has a large specific surface area, composed of wood-based activated carbon, coconut shell-based activated carbon.

Conductive adhesive is used to improve the electrical conductivity of the activated carbon to facilitate the delivery of energy to the collector, and so far, manufacturers have generally used carbon black as a conductive additive for supercapacitors.

Electrolyte, also called electrolyte, provides the anions and cations of the double electric layer, and its performance directly affects the life of the supercapacitor, which is divided into two categories: aqueous electrolyte and organic electrolyte. Its key parameters are electrical conductivity, electrochemical stability, thermal stability and safety.

Diaphragm has ion penetration, the positive and negative electrodes apart, so as not to have ionic carbon migration short circuit allows the electrolyte anion and cation free passage. Diaphragm is generally made of fiber-like material, forming a supercapacitor 30% impedanc.

Operating Principle

When charging, the electrode is applied voltage, and the anion and cation in the electrolyte are passed through the diaphragm by the electrostatic action of the electrode, and stored in the dense pores of the activated carbon. When discharging, the electrons on the collector migrate from the outer circuit to achieve the output current, and the anion-cation combination returns to the electrolyte state after discharge.

Application Characteristics

Supercapacitors have advantages including.

(1) high power density, is 10~100 times of the ordinary battery, up to 10kw/kg. can instantly release larger energy, charging speed is also faster.

(2) Long cycle life, long time working capacity is not easy to decay, to meet the requirements of the life of the meter.

(3) Wide operating temperature, ordinary batteries at low temperature chemical reaction is weak, while the supercapacitor can generally work in the temperature range of 40 ℃ ~ 70 ℃, to meet the requirements of the working environment of the power meter".

Disadvantages are mainly.

(1) large end voltage fluctuation, due to the supercapacitor stored energy and end voltage square proportional to the square, so when the release of energy when the end voltage decreases accordingly, it is difficult to be used as a constant voltage source, the energy density is low, the energy storage depends on the physical energy.

Low energy density, energy storage by physical means, difficult to compare with chemical batteries.

Application Circuitry

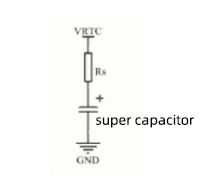

Take the single-phase smart energy meter of the State Grid as an example, the power supply system generally adopts linear transformer to rectify the utility voltage and then passes through LD0, DCDC and other DC voltage conversion devices to supply the microcontroller and other functional modules. Supercapacitors are generally charged by constant voltage series resistance, and the simplified circuit schematic is as follows.

Power supply The VRTC charges the supercapacitor through the current limiting resistor RS. As the voltage of the supercapacitor rises, the voltage at the two ends of RS decreases, the charging current gradually decreases, and after the charging is completed, this circuit does not generate power consumption. When the supercapacitor is powered, it directly outputs current to the RTC power supply to ensure the normal operation of the clock.

Selection Recommendation

According to the different production processes, small supercapacitors used in energy meters can be divided into two types: button type and column type.

(1) Buckle-type supercapacitor: the positive and negative shells are made of stainless steel, which can be used as a fluid collector and play the role of a container. The activated carbon electrodes are glued onto the positive and negative shells respectively. Positive electrode, diaphragm and negative electrode are moistened with electrolyte and stacked into a sandwich shape, which is sealed with a sealing ring.

Button type supercapacitor has better sealing and smaller leakage current, but the positive and negative electrodes are isolated by gaskets and coiled and riveted together, which has the risk of short circuit due to the rusting of the pole pieces.

(2)Column-type supercapacitor: The positive and negative electrodes and the diaphragm are wound into a cylindrical core, which is connected with the cover plate and then installed into the aluminum shell. After impregnation and filling with electrolyte, the aluminum shell and cover are sealed. The manufacturing process is similar to that of ordinary aluminum electrolytic capacitors.

Column type supercapacitor has a larger capacity than button type capacitor in general due to the larger area of coiled activated carbon electrodes, but the self-discharge phenomenon is more active than button type due to the closer distance of pole plates.

Voltage Characteristics

The withstand voltage of supercapacitor is determined by the electrolyte, generally the decomposition voltage of water-based electrolyte is 1.0~1.6V, and organic electrolyte is around 2.8V. In order to satisfy the application of power meter, the super capacitor should adopt organic electrolyte and the form of multi-slice series connection. General power meter using 5V power supply, 2 pieces in series after the withstand voltage 5.5V or so, 3 pieces in series after the withstand voltage 7.5V or so, in order to ensure the reliability of operation, at least 2 pieces in series.

UF Capacitors is established since 1995, as one of the professional China Capacitor manufacturer in China, we are strong in complete management, strict quality control system, and excellent sales service. UF Capacitors supply high quality Capacitors ,help customers cost down 20%-50%.

UF Capacitors is an ISO9001-certified manufacturer in China, founded in 1995. We hold military qualifications for tantalum capacitors, MLCC, and other products. Additionally, we have a UL-recognized test laboratory located at our factory site.

Our marketing position is to provide a superior alternative to first-tier brands such as TDK, Murata, AVX, EPCOS, Vishay, and Panasonic. We offer similar quality but at better prices, with faster lead times and excellent service. With extensive experience working with renowned international companies like GE, Philips, Jabil, and Flex, we have built a strong reputation.

UF Capacitors serves the consumer electronics, computing, communications, and industrial markets. As a professional Chinese electronic components manufacturer, we are dedicated to delivering high-quality electronic components, exceptional management, strict quality control systems, and excellent sales service. We strive to foster mutually beneficial partnerships and drive business growth.

See UF Capacitors Cross Reference as follow:

|

Description |

UF Capacitors |

Vishay |

Eaton |

ELNA |

Panasonic |

Cornell Dubilier |

|

TSE series |

196 DLC series |

KR series |

DSK series |

SG Series |

EDC Series |

More Details please browse our website:www.ufcapacitors.com