NTC thermistor (Negative Temperature Coefficient Thermistor) is a kind of oxide sintered by manganese (Mn), nickel (Ni), copper (Cu), etc. NTC thermistor is a kind of semiconductor resistor whose resistance value changes with the change of temperature in the opposite tendency and the rate of change is great. Usually, thermistors can be used for temperature detection, temperature compensation, and anti-surge applications.

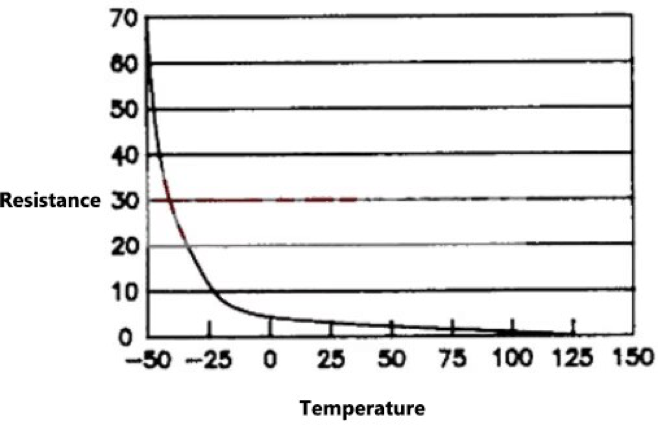

NTC thermistor resistance (RT) and thermodynamic temperature (T) of the typical relationship between the curve shown in the figure below, can be seen with the increase in temperature, RT rapidly decreases!

The above can be expressed as an exponential relationship using the following equation

Temperature sensors and nonlinear correction

NTC thermistor is a class of industrial temperature measurement in the field of temperature sensors are widely used. Compared with the semiconductor integrated temperature sensor, NTC thermistor has a wide temperature range, easy to use, inexpensive and so on; compared with platinum RTDs or thermocouples, NTC thermistor has a high sensitivity, simple circuitry, inexpensive features.

Thermistor temperature measurement range up to -100 ℃ ~ 500 ℃, its sensitivity up to -44000ppm / ℃ (25 ℃ when), the actual use of its size is very flexible, can be as small as 0.01 inches or smaller diameter, the maximum almost no limit. The rated room temperature resistance depends on its semiconductor material, size, shape, and the contact area of the electrodes. Thick and narrow thermistors have relatively high resistance values, while thin and wide shaped ones have lower resistance values.

Since good linearity is usually required when used as a temperature sensor. However, the resistance of a thermistor varies exponentially with temperature, and over a wide range of temperatures, the relationship between resistance and temperature has a relatively severe nonlinearity. At this time, a nonlinearity correction will achieve better results.

Usually used NTC thermistor nonlinear correction is the use of a temperature coefficient of small fixed resistance and thermistor in parallel, this method is simple and easy to use and better correction effect, it has the NTC thermistor curve of the cold end of the role of the downward pull.

The above figure shows the temperature characteristic curve of the thermistor itself and the temperature characteristic curve after correction of the parallel resistance. Two resistors in parallel, the role of the lower resistance value is greater, in the cold end (close to T1) thermistor value resistance value is higher, the parallel fixed resistor plays a major role, the thermistor itself is steeper resistance change (large temperature coefficient) due to the role of the fixed resistor and become flat; and the hot end (close to T4), the thermistor relative to the fixed resistor resistance value is low, so the role of the thermistor's resistance change is obvious.

For the fixed resistor resistance value used for parallel correction can be determined using the following formula:

Where RT1 is the resistance of the thermistor at the lowest temperature in the temperature range, RT3 is the resistance at the highest temperature in the temperature range, and RT2 is the resistance at the midpoint of the temperature range.

The calibrated thermistor temperature characteristic curve is a very flat S-shape, with the midpoint of the S-shape close to the midpoint of the calibration temperature. In the calibration temperature range, the temperature measurement error is small, and the error increases very significantly beyond the range. In order to understand the error of the whole temperature range, mathematical tools such as excel or matlab can be used to carry out detailed calculations of the calibration of different temperatures.

Anti-surge protection

Another very wide use of NTC thermistor is the anti-surge current protection of the power supply, the schematic diagram is shown as follows

As in the rectifier filter circuit, in order to avoid the momentary inrush current generated by the capacitive load charging at the moment of power-on of the electronic circuit, a power type NTC thermistor is usually connected in series in the power supply circuit. This can effectively resist the inrush current when the power on, and in the completion of the role of resisting the inrush current, due to the continuous action of the current through the NTC thermistor resistance will fall to a very small value, the consumption of power is very small can be ignored, will not affect the normal operation of the circuit. Therefore, in small and medium power power supply circuit, the method of using power type NTC thermistor to resist power-on inrush current is widely used.

The main parameters of power type thermistor are: maximum steady state current, R25 resistance, dissipation factor, B value, etc. The maximum steady state current is the maximum current of the thermistor.

The maximum steady state current is the maximum continuous current value allowed to be applied to the thermistor at 25℃ ambient temperature. This value must be higher than the thermistor operating current in the actual circuit.

R25 Resistance Value is the design resistance value of the thermistor, i.e., the zero-power resistance value at 25℃ (usually the resistance value accuracy is about 20%). This value can indicate the current limiting capability of the thermistor at the moment of power-on.

B value is the thermal sensitivity coefficient, which is the ratio of the difference between the natural logarithm of the zero power resistance value at two temperatures and the difference between the inverse of these two temperatures (see the thermistor temperature characteristic formula). the larger the B value is, the smaller the residual resistance is, and the smaller the operating temperature rise is.

Dissipation coefficient is the ratio of the change in power dissipated by the device itself to the corresponding change in temperature at a specified ambient temperature.

Thermal time constant refers to the zero-power conditions, when a sudden change in temperature occurs, the thermistor surface temperature talk about the beginning to the end of the time required for 63.2% of the time value.

Generally, the larger the product of thermal time constant and dissipation factor, the larger the thermal capacity of the thermistor, and the stronger the ability to resist inrush current.

UF Capacitors is established since 1995, as one of the professional China Capacitor manufacturer in China, we are strong in complete management, strict quality control system, and excellent sales service. UF Capacitors supply high quality Capacitors ,help customers cost down 20%-50%.

UF Capacitors is an ISO9001-certified manufacturer in China, founded in 1995. We hold military qualifications for tantalum capacitors, MLCC, and other products. Additionally, we have a UL-recognized test laboratory located at our factory site.

Our marketing position is to provide a superior alternative to first-tier brands such as TDK, Murata, AVX, EPCOS, Vishay, and Panasonic. We offer similar quality but at better prices, with faster lead times and excellent service. With extensive experience working with renowned international companies like GE, Philips, Jabil, and Flex, we have built a strong reputation.

UF Capacitors serves the consumer electronics, computing, communications, and industrial markets. As a professional Chinese electronic components manufacturer, we are dedicated to delivering high-quality electronic components, exceptional management, strict quality control systems, and excellent sales service. We strive to foster mutually beneficial partnerships and drive business growth.