MLCC - Multilayer Ceramic Capacitor, commonly known as surface-mount capacitor, can cause noise and whining issues. Why is this?

Sound originates from the vibration of objects, and sound waves with frequencies between 20Hz and 20kHz can be recognized by the human ear. The whining sound emitted by MLCC means that, under the influence of voltage, MLCC undergoes significant vibrations (microscopic in amplitude, less than 1nm)."

Why does MLCC vibrate?

Before understanding why MLCC vibrates, we need to first grasp a natural phenomenon. Under the influence of an external electric field, all substances undergo dimensional changes – this is known as electrostrictive deformation."

For certain ferroelectric materials with high dielectric constants, the electrostrictive deformation is pronounced and is referred to as the piezoelectric effect.

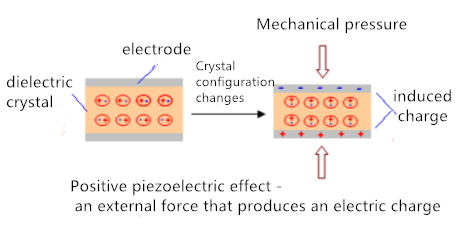

The definition of the piezoelectric effect is as follows: When pressure, tension, or shear forces are applied to a crystal without a symmetric center, a proportional polarization of the medium occurs. Simultaneously, positive and negative charges appear on the two end faces of the crystal. This phenomenon is known as the direct piezoelectric effect. Conversely, when an electric field is applied to the crystal, causing polarization, deformation or mechanical stress proportional to the electric field strength occurs. This phenomenon is known as the inverse piezoelectric effect. Both the direct and inverse piezoelectric effects are collectively referred to as the piezoelectric effect."

Direct Piezoelectric Effect: Applying mechanical pressure to a dielectric material with piezoelectric properties causes structural rearrangement in the crystal, inducing charges on the material's surface and generating a potential difference."

Inverse Piezoelectric Effect: Applying voltage to a dielectric material with piezoelectric properties results in mechanical stress and deformation."

UF Capacitors Ceramic Capacitor introduction:

UF is a well-known and respected capacitors manufacturer and factory based in China, with a history dating back to 1995. We have earned the prestigious ISO9001 certification, reflecting our commitment to quality and excellence in the production of electronic components.

Our technical team is mainly composed of experienced and outstanding engineers from well-known companies such as Yagoe, Fenghua, Huak etc. Most of our team members hold graduate degrees. In our industry, we are at the forefront in both technology and management.

Our equipment is currently the most advanced and high-end in the country. In the production and manufacturing of MLCC (Multilayer Ceramic Capacitors), materials, formulations, processes, and equipment manufacturing are crucial. Among them, the extrusion equipment is the most critical, and our extrusion equipment comes from Japan's Hirano, which is a top-tier device comparable to Japan's Murata MURATA equipment. Purchasing such equipment requires a lead time of up to 2 years. Our extrusion equipment can produce at a speed of 80 meters per minute, ensuring highly efficient production capacity.

Our six-sided appearance inspection machine is from Japan's Iwata, and the four-parameter performance testing machine is produced by Japan's Dongrong, both of which boast exceptional performance. They can inspect 7,000 to 10,000 MLCCs per minute. As we use the best equipment from Japan, we ensure high reliability and can meet our customers' quality requirements and demands.

In summary, the MLCCs we produce are designed and manufactured to be on par with top brands like Murata and TDK, exhibiting excellent quality without any compromise.