Capacitors are crucial electronic components that store and release electrical energy. They are widely utilized in

various electronic devices and circuits to manage voltage fluctuations, filter signals, and store energy temporarily.

Among the diverse types available, electrolytic and ceramic chip capacitors stand out due to their unique

characteristics and applications.

Aluminum Electrolytic Capacitors:

Construction of Aluminum Electrolytic Capacitors

Aluminum Electrolytic capacitors are designed with two conductive plates (anode and cathode) separated

by an electrolyte-soaked paper, wound into a cylindrical or rectangular form. The electrolyte determines

the capacitance and is a key factor in their ability to provide high capacitance values in relatively compact

sizes.

Characteristics and Properties of Aluminum Electrolytic Capacitors

Polarity Sensitivity: This type of capacitor is polarized, necessitating careful attention to the positive and

negative terminals during installation. Reverse polarity can cause malfunction, leakage, or in extreme

cases,explosions.

Capacitance Range: Electrolytic capacitors excel in offering high capacitance values, typically ranging

from microfarads to even several farads. This characteristic makes them ideal for applications demanding

significant capacitance, such as power supply filtering and energy storage.

Voltage Ratings: They often have relatively high voltage ratings compared to other capacitor types, making

them suitable for applications where higher voltages are involved.

Applications and Use Cases of Aluminum Electrolytic Capacitors

The unique properties of electrolytic capacitors find application in various domains:

Power Supply Filtering: They effectively smooth voltage ripples in power supply units, ensuring stable

DC output.

Audio Systems: Electrolytic capacitors are used in audio circuits, particularly in coupling and signal filtering.

Amplifiers: As coupling capacitors in amplifier circuits, they block DC while allowing AC signals to pass

through, enabling efficient amplification.

UF Capacitors supplies a wide range of SMD Aluminum Electrolytic Capacitors (Chip Type):

standard series #TCS, standard & wide temperature series #TCK, low impedance series #TLZ ,

extra low impedance series #TKZ and long life extra low impedance series #TFZ SMD electrolytic

capacitors. Now UF Capacitors TFS Series Chip Type, SMD Electrolytic Capacitors features with

long life upto 5000hours, Low impedance,Low ESR and small size. This miniature size SMD

electrolytic capacitors TFS series are perfect replacement of Panasonic FT series, following cross

table FYI:

|

|

Description |

UF Capacitors |

Rubycon |

Nichicon |

Panasonic |

|

|

TCS 85C V-Chip Aluminum Electrolytic |

SEV Series |

UWX Series |

EEE-X(A)S Series |

|

|

|

TCK 105C V-Chip Aluminum Electrolytic |

SKV Series |

UWT Series |

EEEHA Series |

|

|

|

TFZ 105C 2000-5000 long life with extra lower impedance Aluminum Electrolytic |

TZV Series |

UUD Series |

EEE-FK Series |

|

|

|

TLZ 105C 1000-2000h |

SZV Series |

UCL Series |

EEE-FC Series |

|

|

|

TMA 105C 2000h conductive polymer aluminum solid Aluminum Electrolytic |

PAV Series |

CV Series |

SVPE Series |

|

|

|

TMB Series 105C 2000h conductive polymer aluminum solid Aluminum Electrolytic |

PAV Series |

CV Series |

SVPC Series |

Ceramic Chip Capacitors:

Construction of Ceramic Chip Capacitors:

Ceramic chip capacitors are compact and non-polarized components composed of ceramic materials with

conductive metal layers acting as electrodes. These layers are stacked together to enhance capacitance

while maintaining a small form factor.

Characteristics and Properties of Ceramic Chip Capacitors:

Size and Miniaturization: Ceramic chip capacitors are significantly smaller compared to electrolytic capacitors.

Their miniature size makes them ideal for applications where space is a constraint.

Capacitance Range: They offer lower capacitance values compared to electrolytic capacitors, usually ranging

from picofarads to a few microfarads. However, advancements in technology have led to higher capacitance

variants.

Frequency Response and ESR: Ceramic chip capacitors exhibit a higher frequency response and lower

equivalent series resistance (ESR) compared to electrolytic capacitors, making them suitable for high-frequency

circuits and noise suppression.

Applications and Use Cases of Ceramic Chip Capacitors:

Ceramic chip capacitors are extensively used in various applications:

High-Frequency Circuits: Due to their low ESR and high frequency response, they are preferred in RF circuits

and high-speed digital circuits.

Decoupling Capacitors: These capacitors are placed close to integrated circuits to provide instantaneous power

when needed, reducing voltage fluctuations.

Noise Suppression: Their low ESR makes them effective in minimizing electromagnetic interference (EMI)

and noise in electronic circuits.

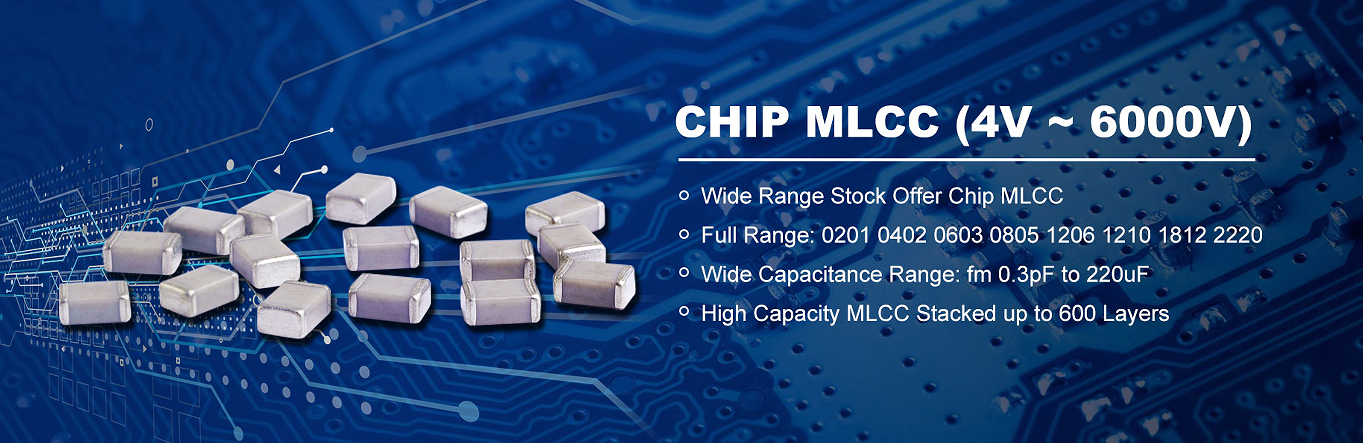

UF Capacitors MLCC consists of a conducting material and electrodes. To manufacture a chip-type

SMT and achieve miniaturization, high density and high efficiency, ceramic condensers are used.

MLCC is made by NP0. X7R, X5R and Y5V dielectric material and which provides product with

high electrical precision, stability and reliability. Now UF Capacitors offer standard MLCC series,

high voltage MLCC series, and High Q series.

High Q series: High Q and ultra-low power consumption Low ESR, capacitors from 0.1pF to

100000pF. Voltage: 50V to 7200V, Series: 0402. 0505. 1111. 0603. 0805. 2525. 3838..

|

Photo |

Descriptiom |

UF Capacitors' |

TDK/Epcos |

Murata |

Kemet |

|

|

CT41 Chip Multilayer Ceramic Capacitors |

CT41 Series |

C1005 Series |

GRM Series |

C0201 Series |

Summarizing the Differences

Size and Form Factor: Electrolytic capacitors are larger in size, while ceramic chip capacitors

are significantly smaller and more compact, enabling miniaturization in electronic devices.

Polarity Sensitivity: Electrolytic capacitors require attention to polarity during installation,

whereas ceramic chip capacitors are non-polarized, simplifying their use.

Capacitance Range: Electrolytic capacitors offer higher capacitance values compared to

ceramic chip capacitors, catering to applications requiring substantial capacitance.

Voltage Ratings: Electrolytic capacitors generally have higher voltage ratings, making them

suitable for applications involving higher voltages.

Understanding the nuanced differences between electrolytic and ceramic chip capacitors

is imperative for engineers and hobbyists when selecting components for electronic circuits.

The choice should be based on the specific requirements of the application, considering

factors such as size constraints, desired capacitance, voltage ratings, and frequency response.

By leveraging the distinctive features of electrolytic and ceramic chip capacitors, engineers can

design more efficient and reliable electronic systems tailored to their unique needs.

UF Capacitors is an ISO9001-certified manufacturer in China, founded in 1995. We hold

military qualifications for tantalum capacitors, MLCC, and other products. Additionally, we

have a UL-recognized test laboratory located at our factory site.

Our marketing position is to provide a superior alternative to first-tier brands such as TDK, Murata,

AVX, EPCOS, Vishay, and Panasonic. We offer similar quality but at better prices, with faster lead

times and excellent service. With extensive experience working with renowned international companies

like GE, Philips, Jabil, and Flex, we have built a strong reputation.

UF Capacitors serves the consumer electronics, computing, communications, and industrial

markets. As a professional Chinese electronic components manufacturer, we are dedicated

to delivering high-quality electronic components, exceptional management, strict quality control

systems, and excellent sales service. We strive to foster mutually beneficial partnerships and

drive business growth. If you are looking for a reliable China supply to replace 1st tier brands,

UF capacitors is definitely your right choice.